SCULPTURE ENLARGEMENTS & REDUCTIONS

– 4 AXIS CNC ROUTER – RESIN PRINTING – WAX PRINTING –

At American Bronze, we can create 3D digital scans and reductions or enlargements of your project with our 4–axis CNC router, high-quality resin, or wax printer. This service allows us to scale your project to any desired size with either a digital or physical model that we create, or one that you provide. To be clear, if you have a project you would like to begin, and do not have a file or model our digital artist can create one for you.Sculpture enlargements

By offering this service our foundry gives you the opportunity to recreate any object, at any scale, without having distortions. On top of that our high–quality foam can be carved and clayed to a fine level of detail. No matter what size you choose, using this service will eliminate a large amount of your time spent on scaling your sculpture and give you time to focus on other projects

Sculpture Enlargements & Reductions – Our Process

- Our skilled and experienced staff will start by scanning your object with our 3D scanner. If you have your own file you would like us to use, we would need a copy that is in the required format.

- Once the scanning process is complete, the project will be scaled up or reduced to your desired size preserving the fine detail. Once we finish with the proper adjustment on your file it will be sent to you for approval.

- Once we receive your approval, we can begin the milling or printing process.

- Depending on the size of your project it may be printed as a whole or in pieces. Either way we will assemble and attach all pieces, unless requested not to.

- After your project is assembled a hard coating is applied over the foam, so the detail of the foam is preserved and the clay may stick to it properly.

- At this point, your project will be ready to ship or have the clay applied to its surface. Sculpture enlargements

Resin Printing

Most things under 3 feet are created from our resin printer. We chose to use a resin printer over a 3D printer because it eliminates the print lines in the artwork. We also have no bracing that would need to be removed. You would also be able to have a mold made of your sculpture, for replications or editions.

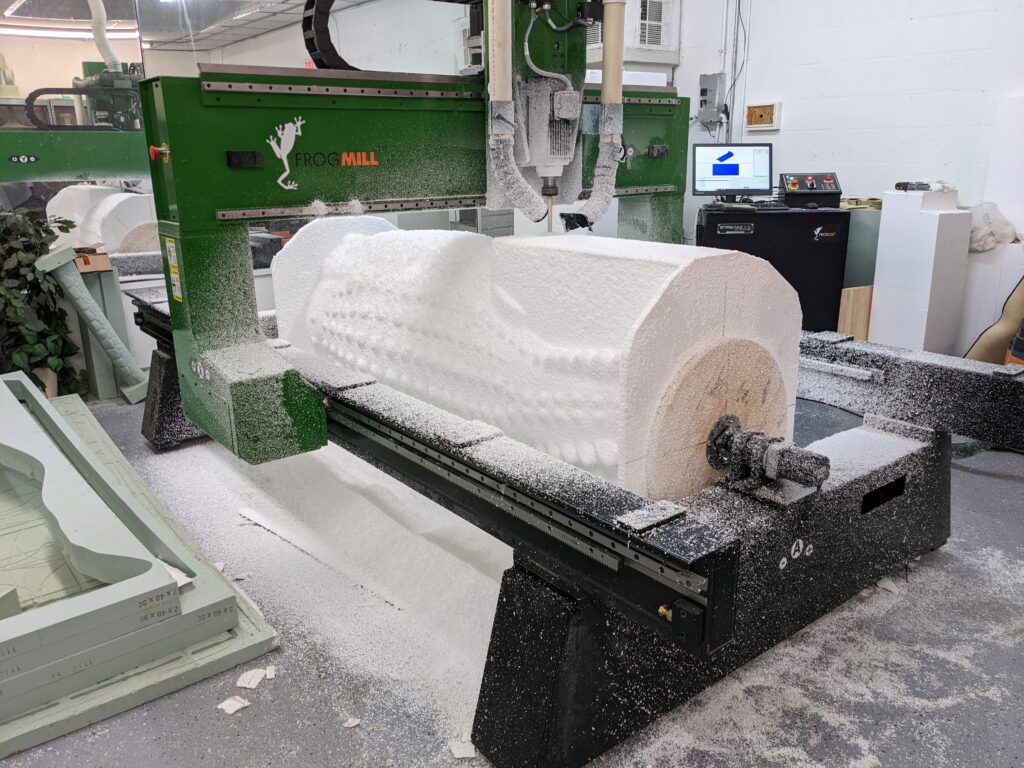

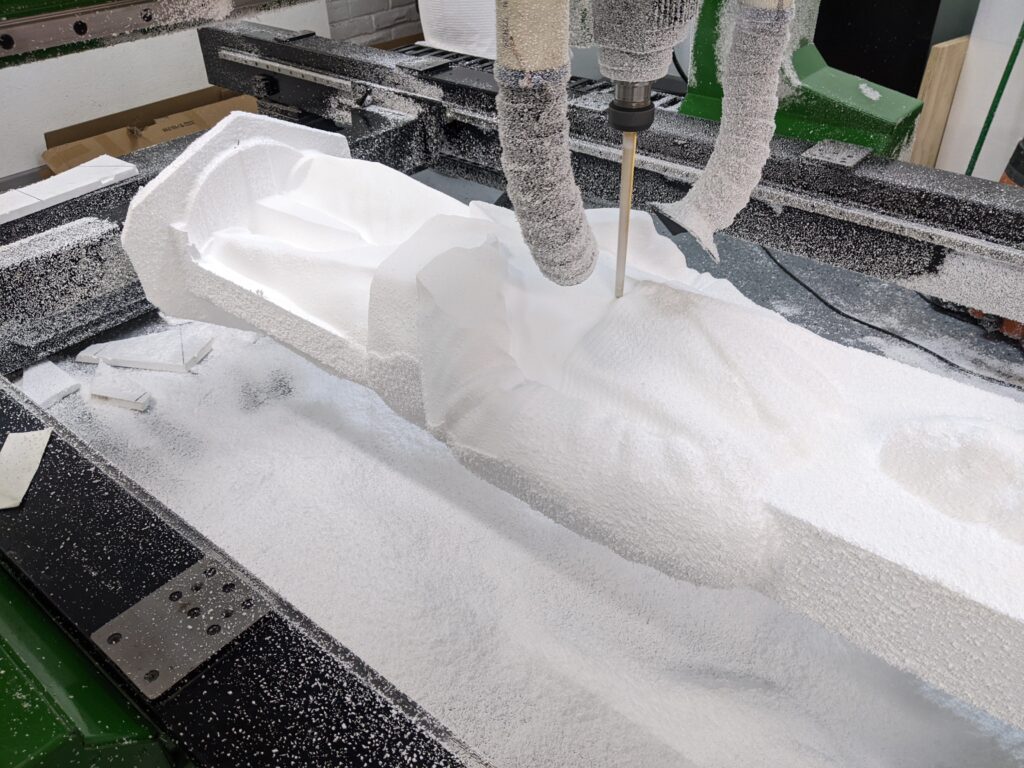

Mill Cut

Depending on the size most pieces above 3 feet are cut on our mill. The mill is a subtractive process, in which we start with a block of foam similar to the size of your sculpture and remove material. Not only does the mill allow a large piece to be cut at once, but it also allows us to cut specific pieces to create a monumental sculpture if desired.

Wax Printing

Wax printing is similar to our Resin Printing process, also being an additive 3D process. The largest difference between the two is that Wax Printing does not require a mold. That being said you will get a one-of-a-kind sculpture since it goes directly into our ceramic shell mixture, after being sprued.

Benefits of us having in-house resources

All our Resources

Your project will be achieved within the same company. Meaning you do not have to bounce between companies to get information. We will use our own time, employees and resources to complete your project.

Cared for by Hand

We are not a production facility; we are a Fine Art Bronze Foundry. This ensures that your project will be treated as a piece of art. Because of that we have a team of skilled and talented artists that work on your piece by hand. Each step from start to finish is done by hand, making sure your work stays true to you as an artist.

Quality Control

We have direct control over quality, because we have control over the process from start to finish and will communicate with you for every step. That also means we have control over timelines to make sure your project stays on track.